Are you constantly seeking ways to optimize your centrifugal pump operations and reduce costs? Imagine having the power to instantly calculate the efficiency of your pumps with a simple tool.

The Centrifugal Pump Efficiency Calculator is here to transform the way you assess and improve your pump performance. This tool is not just a luxury; it’s a necessity for anyone looking to enhance energy efficiency and ensure optimal functioning of their pump systems.

Picture this: a streamlined process that saves time, resources, and money while maximizing performance. By understanding the efficiency of your centrifugal pumps, you can make informed decisions that lead to significant improvements in operational effectiveness. This article will guide you through the benefits, functionalities, and importance of using an efficiency calculator, empowering you to take control of your pump systems like never before. Dive in to discover how this tool can be the game-changer in your maintenance toolkit.

Centrifugal Pump Basics

A centrifugal pump has several key components. The impeller spins and moves liquid. The casing holds the liquid and directs flow. Shaft connects the impeller to the motor. Bearing supports the shaft. Seal prevents leaks. Together, these parts help the pump work.

Centrifugal pumps use a simple principle. The motor turns the impeller. The impeller spins fast. Liquid moves from the center to the edge. This motion creates pressure. The pressure pushes the liquid out of the pump. The liquid then flows through pipes. This is how a centrifugal pump works.

Factors Affecting Efficiency

Flow rate measures how much liquid moves in a pump. Faster flow can improve efficiency. But too fast can cause problems. Control is key. A balanced flow keeps the pump working well.

Head pressure shows the force needed to move liquid. Higher pressure can mean more energy use. But it helps in moving liquids far distances. Keep head pressure steady for best results.

Impeller design affects how a pump works. A good design moves liquid smoothly. It saves energy and boosts efficiency. Simple designs often perform better. They reduce wear and tear.

Fluid characteristics are important. Thick liquids need more power to move. Thin liquids flow easily. Temperature also matters. Hot liquids can change the pump’s performance. Always consider the type of fluid used.

Importance Of Efficiency Calculation

Efficient pumps save energy. Lower energy means less electricity used. This helps the environment. Energy-efficient pumps reduce carbon emissions. They also lower your bills. Save money and the planet at the same time.

Inefficient pumps cost more to run. They use more power. This increases expenses over time. Maintenance costs also rise with poor efficiency. Efficient pumps need fewer repairs. Save money with smart choices.

Efficient pumps last longer. They work better and break less. Long-lasting pumps save money. Fewer breakdowns mean less stress. Investing in efficiency leads to a happier system. It’s a smart move.

Using A Pump Efficiency Calculator

To use the calculator, enter key details first. These include the flow rate, head, and power. The flow rate is how much water moves. The head measures the pump’s height capacity. Power shows how much energy the pump uses. Enter these numbers carefully. They affect the result accuracy. Ensure units are correct, like gallons per minute or meters.

Results show the pump’s efficiency. Efficiency tells you how well the pump works. High efficiency means less energy wasted. Lower values may mean problems. Look at percentage values. Higher percentages are better. Efficiency helps save money on energy bills. It also reduces wear on the pump.

Mistakes can happen if input data is wrong. Wrong units can cause issues. Double-check the numbers you input. Sometimes, calculators don’t match actual conditions. This might affect results. Always refer to the manual for guidance. If results seem off, recheck inputs.

Strategies To Improve Efficiency

Regular maintenanceis key for pump efficiency. Check parts often for wear. Clean filters to prevent blockages. Lubricate moving parts well. Keep records of each check. This helps in finding issues early. Fix small problems quickly. Save money by preventing big repairs. A well-maintained pump lasts longer and uses less energy.

Proper sizingensures the pump works at its best. Choose the right size for your needs. A pump too big wastes energy. A pump too small struggles. Look at flow rate and pressure needed. Consult with experts for sizing help. Correct size means better efficiency. It also leads to lower costs.

Upgrading componentsboosts performance. New parts are more efficient. Upgrade old motors and seals. Consider high-efficiency impellers. Modern components save energy. They also reduce wear and tear. Investing in upgrades pays off. Your pump runs smoother and lasts longer.

Case Studies Of Efficiency Maximization

A factory in Texas improved their pump systems. They reduced energy usage by 20%. They used a simple method. They checked and fixed leaks. They also cleaned the pipes regularly. These small changes helped a lot.

In Germany, a large plant changed their pump size. They picked a pump that matched their needs better. This change saved them money. It also made their system run smoother.

Always check for leaks in systems. They waste energy. Regular cleaning helps pumps work better. Match pump size to the task. This saves money and energy. Small changes can make a big difference.

Future Trends In Pump Efficiency

New technology makes pumps work better. Smart sensors are very important. They help to check the pump’s performance. Sensors find problems before they become big. This saves a lot of energy. It also reduces maintenance costs. Another innovation is advanced materials. These materials make pumps stronger. They help pumps last longer. This keeps them running smoothly.

Sustainable pumps are the future. They use less energy. This helps the environment. Green technologies are popular now. Solar power is one such option. It is clean and renewable. Pumps that use solar power are eco-friendly. Waste reduction is another key focus. It is vital to recycle pump parts. This reduces waste and saves resources. Efficient pumps are good for nature. They help keep the planet healthy.

Frequently Asked Questions

What Is A Centrifugal Pump Efficiency Calculator?

A centrifugal pump efficiency calculator estimates the efficiency of a pump by analyzing input and output energy. It helps in determining how effectively a pump is converting electrical energy into hydraulic energy. This tool is essential for optimizing pump performance, reducing energy consumption, and ensuring cost-effective operation in various applications.

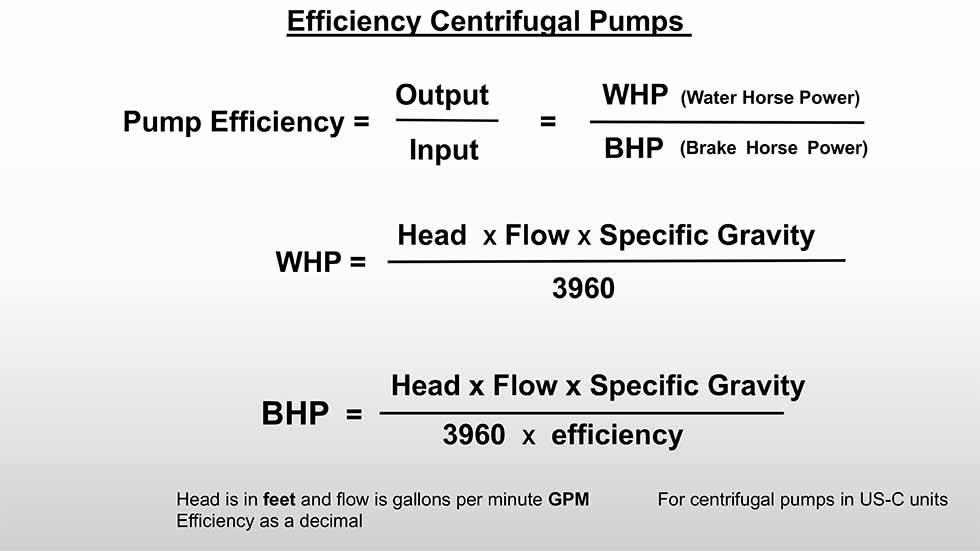

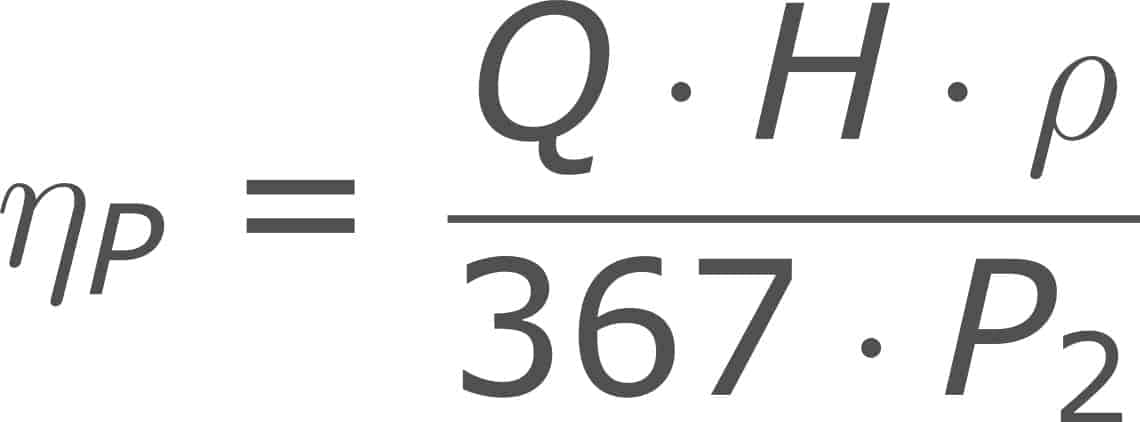

How Do You Calculate Pump Efficiency?

Pump efficiency is calculated by dividing the hydraulic power output by the electrical power input. The formula is: Efficiency (%) = (Hydraulic Power Output / Electrical Power Input) x 100. This calculation helps in assessing the performance and energy consumption of a centrifugal pump in various systems.

Why Is Centrifugal Pump Efficiency Important?

Centrifugal pump efficiency is crucial for reducing energy consumption and operational costs. High efficiency indicates optimal energy use, leading to lower electricity bills and reduced environmental impact. Efficient pumps also have longer lifespans, require less maintenance, and enhance the overall reliability of fluid handling systems.

What Factors Affect Centrifugal Pump Efficiency?

Several factors affect centrifugal pump efficiency, including impeller design, flow rate, and operating conditions. Proper maintenance, correct sizing, and regular performance monitoring also play crucial roles. Ensuring optimal conditions for these factors can significantly enhance pump efficiency, leading to better energy use and cost savings.

Conclusion

Centrifugal pump efficiency calculators simplify energy management. They help reduce costs. Accurate calculations ensure optimal pump performance. Efficiency leads to better resource use. Understanding pump efficiency aids in system maintenance. It improves operational reliability. With these tools, businesses can enhance productivity.

They also contribute to environmental sustainability. Regular monitoring keeps systems running smoothly. Calculators are essential for informed decision-making. By using them, you maximize efficiency in various applications. Engage with these tools for smarter energy use. They are a valuable resource in modern industries.

Stay efficient and save resources with ease.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance