Imagine a world where you never have to worry about the efficiency and reliability of your equipment. Chemical diaphragm pumps are designed to offer just that.

Whether you’re working in a laboratory, a manufacturing plant, or any environment that requires precise fluid handling, these pumps can be your perfect ally. But with so many options on the market, how do you find the best chemical diaphragm pump for your needs?

This article is here to guide you through the top choices, ensuring you make an informed decision that boosts your productivity and keeps your operations running smoothly. You’ll discover which pumps stand out in terms of performance, durability, and cost-effectiveness. Plus, learn how to avoid common pitfalls and find the perfect match for your specific requirements. Stay with us as we delve into the world of chemical diaphragm pumps and uncover the best options that promise to transform your workflow. Are you ready to find the pump that could change everything? Dive in and let’s explore together.

Key Features Of Chemical Diaphragm Pumps

Chemical diaphragm pumps are essential tools in industries. They help move fluids safely. They are known for their durability and reliability. Made to handle corrosive substances, these pumps are ideal for tough jobs. The diaphragm acts as a barrier between the fluid and the pump parts. This prevents leaks and keeps the pump working well.

These pumps have adjustable flow rates. You can change the speed to match the job. Maintenance is easy with these pumps. Parts are simple to replace. They are also energy efficient, which saves power. Safety features are built into the design. This ensures smooth operation without accidents.

Chemical diaphragm pumps are versatile. They are used in many industries, from pharmaceuticals to food processing. These pumps are reliable and safe for many applications.

Top Picks For Chemical Diaphragm Pumps

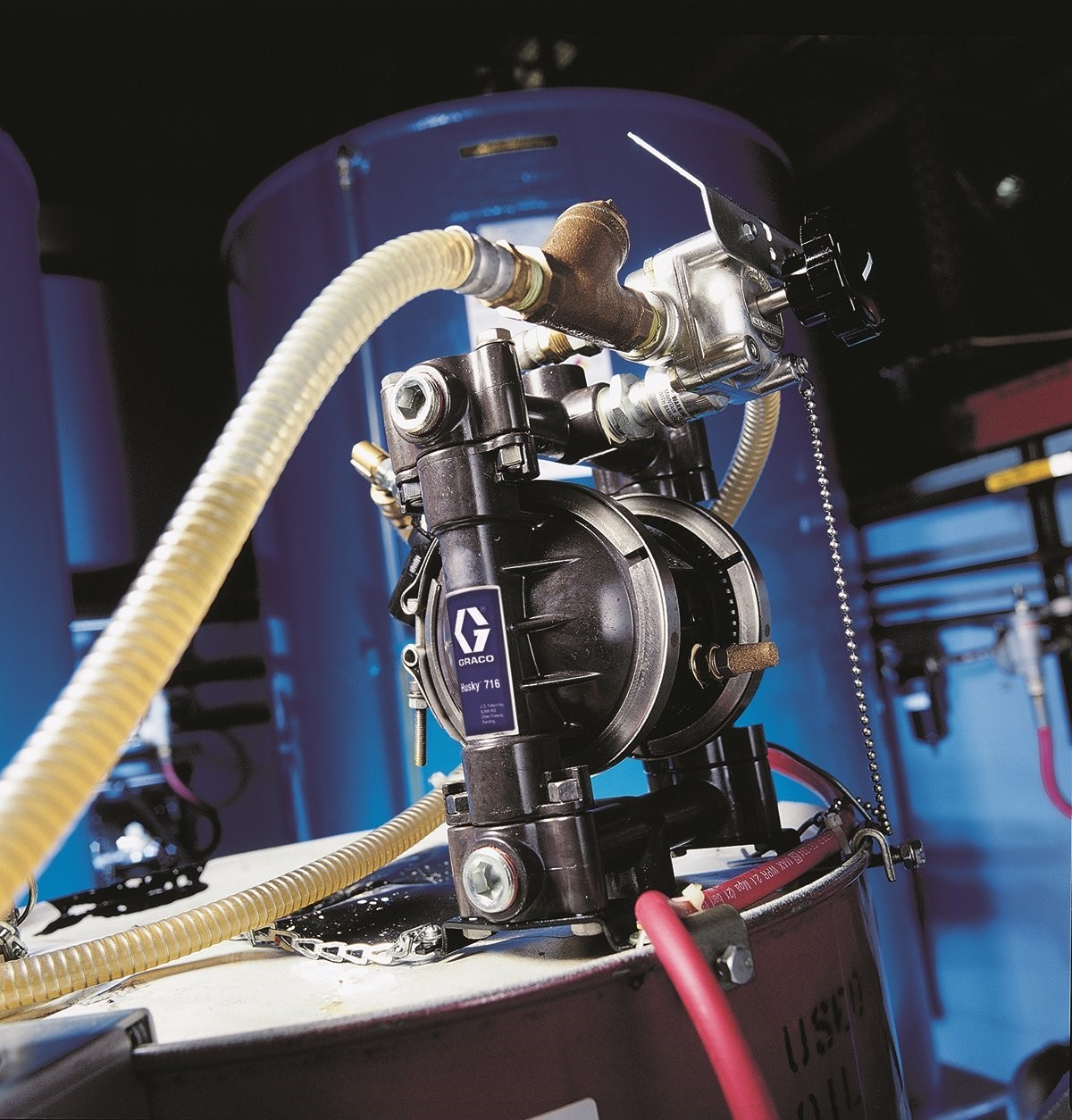

Chemical diaphragm pumps are known for their efficiencyand durability. These pumps handle harsh chemicals with ease. They are built to resist corrosion. Advanced designsensure smooth operation. They offer precise control of flow rates. Ideal for industrial tasks. Some models feature high-pressure capabilities. Perfect for demanding environments.

Affordable diaphragm pumps are available for those on a budget. They offer reliable performancewithout breaking the bank. Simple designsmake them easy to use. They are still effective in chemical applications. These pumps are cost-effective. Great for small businesses or startups. Quality does not always mean expensive.

Portable diaphragm pumps are lightweight and easy to carry. They are compactand perfect for fieldwork. These pumps can fit in small spaces. Ideal for mobile applications. Some models come with easy-to-use handles. Great for quick setups. These pumps make work efficientand convenient.

Factors To Consider When Choosing

Choose a pump with the right material. It should resist chemical damage. Check if the pump materials match your chemicals. This ensures safe and efficient operation. Different materials suit different chemicals. Plastic pumps work with some acids. Metal pumps are for tougher substances. Understanding compatibility is crucial.

The flow rate measures how much liquid moves. Higher flow rates mean faster work. Pressure tells how strong the pump pushes. Choose a pump with enough pressure for your task. Flow and pressure must meet your needs. This ensures efficient pumping. Always check these features before buying.

A durable pump lasts longer. Durability saves money over time. Look for pumps made with strong materials. Less maintenance is better. Easy maintenance saves time. Regular checks ensure the pump runs well. Replace parts when needed. This keeps the pump working safely.

Reviews Of Popular Models

Users find chemical diaphragm pumps reliable for handling chemicals. They like the sturdy design. Easy to use and clean. Some pumps are noisy. Others complain about leakage. Most users agree the pumps work well.

| Pros | Cons |

|---|---|

| Strong build | Can be noisy |

| Handles chemicals well | Some models may leak |

| Easy maintenance | Higher cost |

Most pumps get high ratings. Users rate them 4 to 5 stars. Reliability is important. Sturdy designs are preferred. Few complaints lower scores. Overall, users are happy with their choice.

Benefits Of Using Diaphragm Pumps

Diaphragm pumps are highly efficient. They move liquids smoothly. These pumps need little maintenance. They last a long time. The pump design helps prevent leaks. This keeps operations running without problems. Their reliabilitymakes them popular in many industries.

Diaphragm pumps work in many applications. They handle different types of liquids. Thick, thin, or sticky. They are flexibleand can adapt to different tasks. This makes them useful in food, chemicals, and oil sectors.

These pumps are safeto use. They reduce the risk of spills. They protect the environment by minimizing waste. Their design limits harmful emissions. They help maintain a cleanand safe workplace. This is good for workers and nature.

Maintenance Tips For Longevity

Inspect pumps regularly to ensure they work well. Check for any leaks or cracks. Tighten loose bolts and fittings. Replace worn-out parts quickly. A small check can save big problems later. Always follow the manual for guidance.

Clean the pump after every use. Use water or a mild cleaner. Remove any debris or build-up. Dry all parts before storing. Store the pump in a cool, dry place. A clean pump lasts longer and works better.

If the pump doesn’t start, check the power. Look at the cord and plug. Ensure all connections are tight. If the pump leaks, check the seals. Replace them if they are worn. Listen for strange noises. They might mean something is wrong.

Future Trends In Chemical Pumps

New technologies make pumps work better. Smart systems help pumps learn about problems. Real-time monitoring keeps pumps running smoothly. Advanced sensors stop leaks. Automation saves energy and reduces waste. Improved materials make pumps last longer.

Pumps are getting greener. Less energy use means fewer emissions. Biodegradable parts help the earth. Recyclable materials make pumps eco-friendly. Water-saving designs help conserve resources. Green pumps help the planet.

| Year | Growth Rate (%) |

|---|---|

| 2023 | 4.5 |

| 2024 | 5.0 |

| 2025 | 5.5 |

The pump market is growing fast. More industries need chemical pumps. Global demand is increasing each year. The market size is expanding quickly. Innovations drive growth upwards.

Frequently Asked Questions

What Are Chemical Diaphragm Pumps Used For?

Chemical diaphragm pumps are used for transferring corrosive and abrasive fluids. They are ideal for handling chemicals, acids, and solvents. Their unique design prevents leaks and ensures safety in hazardous environments. These pumps are commonly found in industries like pharmaceuticals, water treatment, and chemical processing.

How Do Diaphragm Pumps Work?

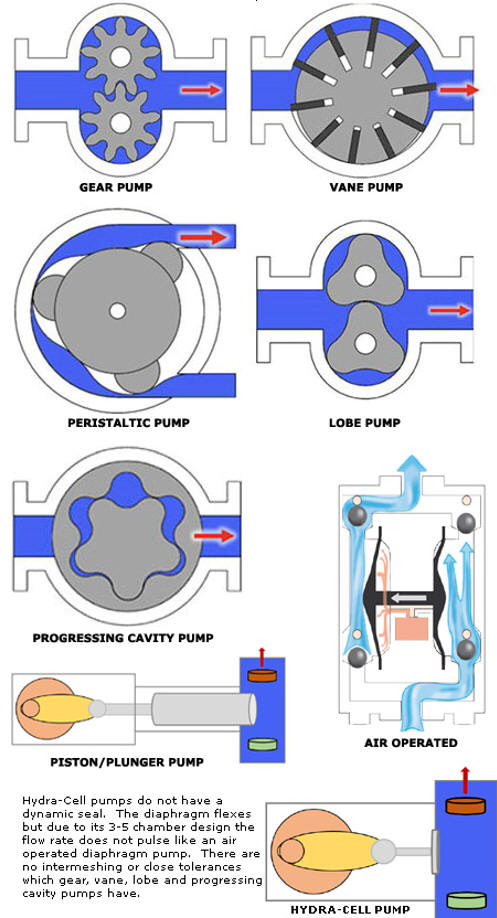

Diaphragm pumps operate by using a flexible diaphragm. The diaphragm moves back and forth, creating a vacuum to draw in fluid. As it moves forward, it pushes the fluid out. This action ensures efficient and leak-free fluid transfer. Their simple design makes them reliable and easy to maintain.

Are Chemical Diaphragm Pumps Energy Efficient?

Yes, chemical diaphragm pumps are energy efficient. They require minimal energy to operate, making them cost-effective. Their efficient design reduces energy consumption while maintaining high performance. This makes them an excellent choice for industries looking to reduce energy costs and environmental impact.

What Materials Are Used In Diaphragm Pumps?

Diaphragm pumps are made from various materials to handle different chemicals. Common materials include PTFE, EPDM, and neoprene. These materials resist corrosion and abrasion, ensuring longevity. The choice of material depends on the chemical compatibility with the fluid being pumped.

Conclusion

Choosing the right chemical diaphragm pump is important. These pumps offer efficiency and reliability. They handle harsh chemicals with ease. It’s vital to consider pump material and capacity. Safety and durability matter too. Investing in a quality pump saves time and costs.

Always consult a professional when in doubt. Proper maintenance extends pump life. Keep operations smooth and efficient. Explore options before deciding. The right pump boosts productivity. Make informed choices for your needs. Find the best fit for your industry. Your processes depend on it.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance