Are you worried about the cost of repairing your centrifugal pump? You are not alone.

Many people like you are searching for reliable information to understand what they might face when it’s time for repairs. Understanding the cost estimate for centrifugal pump repair can save you from unexpected expenses and help you plan better. Imagine knowing exactly what to expect, avoiding surprises, and making informed decisions that benefit your wallet.

We’ll dive deep into what influences these costs and how you can keep them under control, offering you peace of mind and financial security. Stick around to discover practical tips and insights that will empower you in managing your pump repair expenses wisely.

Factors Affecting Repair Costs

Big pumps need more care. Small pumps cost less to fix. Different pump types have different costs. Special pumps need special parts. Common pumps have easy parts. Size and type change repair costs.

Minor damage is easy to fix. Major damage costs more money. Cracked casings need more time. Broken seals need new parts. Wear and tear can be simple or hard. Extent of damage affects repair cost.

Parts in stock are cheaper. Rare parts cost more. Quick delivery saves time. Waiting for parts adds to cost. Old models may need special parts. Parts availability changes repair costs.

Common Repair Procedures

The pump’s seal keeps water from leaking. Over time, seals wear out. Replacing a seal is a common task. A new seal ensures no leaks. Seal replacement can be quick. It usually doesn’t cost much. It’s crucial for pump health.

Bearings help the pump move smoothly. They reduce friction. Damaged bearings can cause noise. Fixing them is important. Repair can involve cleaning or replacing. Good bearings make the pump last longer. The cost varies. It depends on bearing type.

The impeller moves water inside the pump. Over time, it can get worn. Refurbishing involves cleaning or repairing. Sometimes it needs replacing. A good impeller boosts pump efficiency. Costs depend on damage level. Refurbishment can improve performance.

Diy Repairs Vs. Professional Services

DIY repairs can be fun and save money. No need to pay a professional. You learn new skills. But it can be risky. You might make mistakes. Some tools are expensive to buy. Without experience, it’s easy to get stuck. Repairs can take a lot of time. You might spend hours on one small fix.

Call a professional for big repairs. They have the right tools. Experience matters for complex problems. They work faster and safer. If the pump is still under warranty, you should not try fixing it. Professionals can prevent further damage. They ensure the pump runs well. Sometimes, DIY can cost more if you make mistakes.

Cost-saving Tips

Routine checks can prevent big problems. Regular maintenance saves money. It keeps the pump running well. Small fixes stop big repairs. Clean parts work better. Check the pump often. Look for leaks or rust. Tighten loose bolts. Replace worn-out pieces. Good care extends the pump’s life.

Buying parts in bulk reduces costs. Bulk purchase means lower prices. Stores offer discounts for big orders. Keep spare parts handy. Replace parts quickly when needed. Buying in bulk saves time. It avoids urgent purchases. Plan ahead for future needs. Order parts before running out.

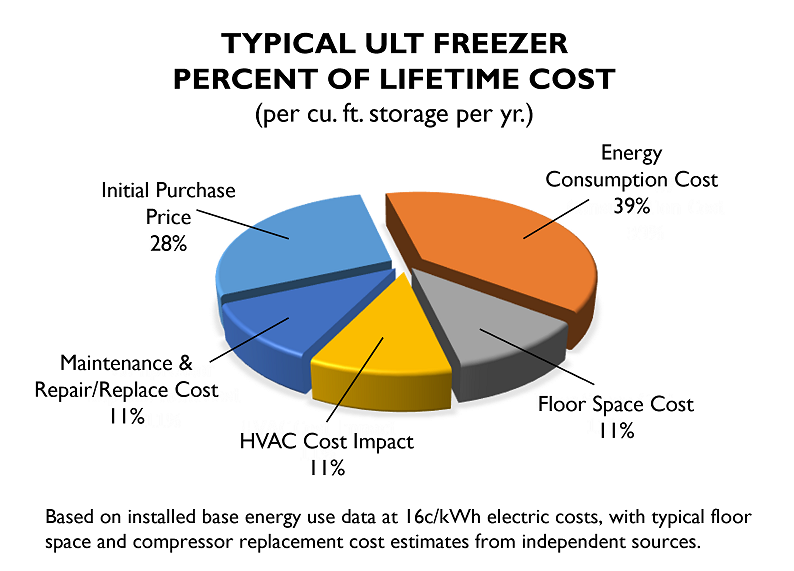

Upgrading for efficiency saves energy. Energy-efficient pumps use less power. They reduce electricity bills. New models work faster. They waste less energy. Upgrade old pumps for better performance. Check for rebates on new models. Efficient pumps last longer. They help save money over time.

Budgeting For Future Repairs

Creating a repair fund is smart. Every month, set aside some money. This money helps with unexpected repair costs. Pumps can break without warning. Having a fund means you are ready. It reduces stress when repairs are needed. Save even a small amount. Over time, it grows. Small savings can make a big difference.

Regular maintenance saves money. Fix small issues before they grow big. This avoids costly repairs later. Long-term savings happen by keeping pumps in good shape. Spending a little now saves more in the future. Consider it an investment. Healthy pumps work better. Good care means fewer repairs.

Choosing The Right Repair Service

Finding a good repair shop is very important. Start by checking local businesses. Ask friends or family for suggestions. Look online for businesses that have good ratings. Some websites let you compare services. Read about each company. Make a list of a few options.

Always check if the service is licensed. Licensed services are safer. They usually do better work. Read reviews from past customers. They can tell you a lot. Look for patterns in feedback. Many bad reviews are a red flag. Good reviews mean happy clients. Choose a service with many positive reviews.

Frequently Asked Questions

What Affects Centrifugal Pump Repair Costs?

Centrifugal pump repair costs are affected by factors like damage severity, parts needed, and labor rates. The pump’s brand and model can also influence costs. Regular maintenance can help in minimizing unexpected repairs and expenses. Always consult a professional for an accurate estimate tailored to your specific pump.

How Often Should A Centrifugal Pump Be Serviced?

A centrifugal pump should be serviced annually to ensure optimal performance. Regular maintenance helps in identifying issues early, preventing costly repairs. However, service frequency might vary based on usage intensity and environmental conditions. Always follow the manufacturer’s guidelines for best results and longevity of your pump.

Are Centrifugal Pump Repairs Cost-effective?

Yes, centrifugal pump repairs are often cost-effective compared to replacements. Repairing extends the pump’s lifespan and restores efficiency. It also avoids the higher upfront cost of new equipment. Regular maintenance can reduce repair frequency, ensuring your pump remains cost-effective over time.

Consulting a professional ensures the best approach.

Can I Repair A Centrifugal Pump Myself?

While basic maintenance can be done, complex repairs require expertise. Attempting repairs without proper knowledge can lead to further damage. It is best to consult a professional for repairs. Experts ensure that the pump is fixed correctly, maintaining its efficiency and lifespan.

This approach minimizes risks and additional costs.

Conclusion

Estimating centrifugal pump repair costs helps plan your budget effectively. Understanding the factors involved ensures you’re prepared for unexpected expenses. Regular maintenance can prevent costly repairs in the future. Always consult with a professional for accurate assessments. This saves time and avoids unnecessary stress.

Keep your pump in good shape for longer life and efficiency. Remember, a well-maintained pump is a cost-effective pump. So, prioritize regular check-ups and timely repairs. It’s the smart way to manage your resources wisely. Stay informed and make educated decisions about your equipment’s care.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance