Have you ever found yourself puzzled by the complexities of sizing a centrifugal pump? You’re not alone.

Understanding the right pump size is crucial for optimizing performance and ensuring efficiency in various applications. Whether you’re dealing with industrial processes, water systems, or HVAC systems, choosing the correct pump size can save you time, money, and headaches down the road.

Imagine the satisfaction of knowing your system is operating at its best, with minimal energy waste and maximum productivity. By mastering the art of pump sizing, you can achieve this level of efficiency. This guide is designed to demystify the process for you, breaking it down into clear, manageable steps. You’ll discover the essential factors to consider, such as flow rate, pressure requirements, and system compatibility, that will empower you to make informed decisions. Don’t let the intricacies of pump sizing intimidate you. Dive into the details with us and unlock the potential for smoother operations and cost savings. Your journey to understanding centrifugal pump sizing begins here, and the rewards are just a few scrolls away.

Basics Of Centrifugal Pumps

Centrifugal pumps move liquid using a spinning impeller. The impeller creates flow by increasing velocity. Pumps work best with constant flow rates. Choosing the right size is important for efficiency. Too big can waste energy. Too small might not pump enough liquid.

Consider the flow rate needed. Measure how much liquid must move per hour. Check the head pressure. This is the height the pump must push the liquid. Pumps have different efficiency levels. Choose one that suits your needs.

Materials matter too. Some liquids need special pump materials. Temperature can affect pump choice. Make sure the pump handles heat well. Always read the manual for specific pump details. This ensures proper use and maintenance.

Key Factors In Pump Sizing

A centrifugal pump needs to handle the right amount of fluid. This is the flow rate. It tells us how much fluid moves in a set time. We measure flow rate in gallons per minute (GPM) or liters per second (L/s). Pick a pump that matches your flow needs. Too much or too little can cause problems.

Pressure head is how high the pump can push fluid. It is measured in feet or meters. The pump must reach the height needed. Think about all the pipes and bends. This affects how far the fluid can go. Choose a pump with the right pressure head.

Different fluids need different pumps. Some fluids are thick or sticky. Others are thin and flow easily. The pump must be strong enough for the fluid type. Check if the fluid is clean or dirty. This matters for choosing the right pump.

Understanding Pump Curves

Performance curveshelp understand a pump’s behavior. They show how much water a pump can move. Each curve has different parts. One part shows flow rate. Another shows pressure. You can see how the pump works at different speeds. The curves help pick the right pump. They show if the pump fits your needs. Flow rateand pressure are important. They tell how strong the pump is. Always check the curves before buying. They are like the pump’s fingerprint.

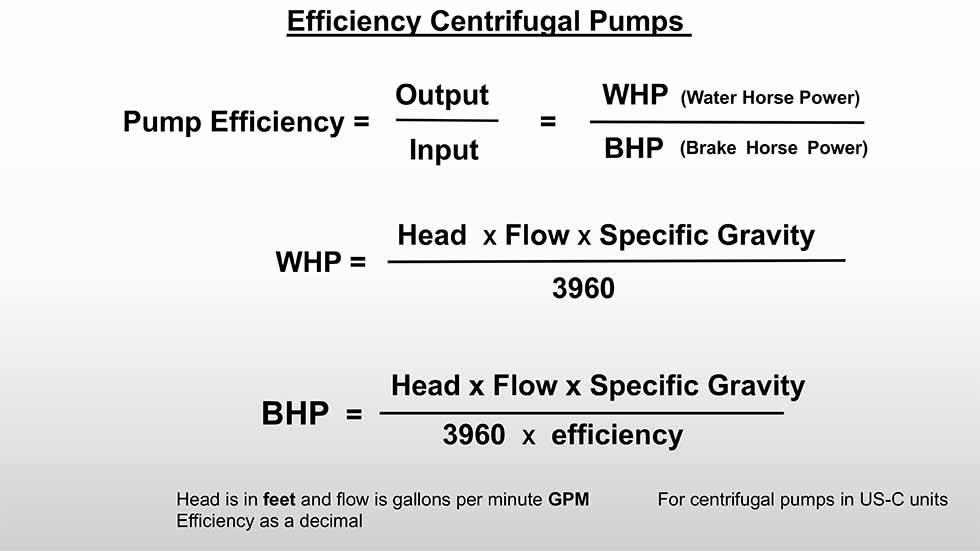

Efficiency curvesshow how well a pump uses energy. High efficiency means less waste. Power curves tell how much energy the pump needs. They help in saving money. Look for pumps with high efficiency. It helps the environment too. Efficient pumps use less energy. They are better for long-term use. Power curvesshow how much power is needed. Choose pumps with lower power needs. It saves energy and money.

Importance Of Net Positive Suction Head

Net Positive Suction Head (NPSH) is very important for pumps. It helps the pump avoid problems like cavitation. Cavitation makes bubbles inside the pump. These bubbles can damage the pump. We need enough NPSH to keep the pump safe. Without it, the pump may break down.

To ensure proper function, check the NPSH available (NPSHa) against the NPSH required (NPSHr). NPSHa must be higher than NPSHr. This keeps the pump running smoothly. Always measure NPSH in meters or feet. Keep these numbers handy for better pump health. Understand NPSH for a happy pump!

System Design And Layout

Pipes carry water to the pump. Choosing the right pipe diameteris crucial. A small pipe can slow water flow. A large pipe can be wasteful. Measure the length of the pipes. Longer pipes need stronger pumps. This helps the water move quickly. Think about the pipe’s material. Smooth pipes help water flow better.

Water moves from low to high places. Elevation changesaffect pump size. Pumps work harder to push water uphill. Measure the height difference. Choose a pump that can handle the climb. Consider the angle of the slope. Steep slopes need more power. Plan carefully for water movement.

Selecting The Right Impeller

Impellers are key parts of centrifugal pumps. They help move the liquid. The size of the impeller matters a lot. It affects how fast the pump can move water. A big impeller can move more water. But it might need more energy. This can make it cost more to run the pump.

A small impeller uses less energy. It might not move as much water. Think about the flow rate you need. Also, consider the pressure the pump must handle. The right impeller size balances these needs. Make sure to check the pump’s manual. It can give good advice on choosing the best impeller.

Avoiding Common Mistakes

Oversizing a pump can cause many problems. A big pump needs more power. This leads to higher costs. It also wears out faster. Efficiency drops as well. The pump may not run smoothly. It could make loud noises. This can disturb the whole system. A smaller pump often works better. It fits the needs perfectly. This saves money and time.

Regular care keeps a pump healthy. Neglecting maintenance leads to breakdowns. Pumps need checks to work well. Parts can wear out over time. Changing them is important. Cleaning is vital too. Dust and dirt can block a pump. This lowers its performance. Always follow a maintenance schedule. This keeps the pump in top shape. It helps avoid costly repairs.

Consulting With Experts

Understanding pumps can be tricky. There are many parts and terms. Professionals can help when things get complex. They know the details that matter most. They can guide you through the process. If you feel lost or unsure, reach out. They have the answers you need. Don’t guess and risk mistakes. Asking for help early can save time. It also avoids costly errors.

Experts know a lot about pumps. They offer valuable insights. These can help in choosing the right pump. Their advice ensures the pump works well. It also lasts longer. They can help with understanding your specific needs. This leads to better choices. Experts can also solve problems quickly. Their experience is a big advantage. With them, you get the best results.

Frequently Asked Questions

What Factors Affect Centrifugal Pump Sizing?

Centrifugal pump sizing depends on flow rate, head, fluid properties, and system layout. Accurate calculations ensure efficiency and reliability. Consider pump type, impeller size, and power requirements. Proper sizing avoids operational issues and enhances performance. Consult manufacturer guidelines for detailed specifications.

How Do I Calculate Pump Flow Rate?

To calculate pump flow rate, determine the volume of fluid moved per unit time. Use the formula Q = A × V, where Q is flow rate, A is cross-sectional area, and V is velocity. Ensure measurements are accurate for precise calculations.

Adjust based on system requirements.

Why Is Head Important In Pump Sizing?

Head is crucial because it represents the energy needed to move fluid through a system. It affects pump efficiency and performance. Proper head calculation ensures the pump can overcome system resistance. Consider static, friction, and dynamic heads for accurate sizing.

Can Pump Sizing Affect Energy Consumption?

Yes, incorrect pump sizing can lead to increased energy consumption. Oversized pumps waste energy by operating inefficiently. Undersized pumps may struggle to meet system demands, causing excess wear. Proper sizing optimizes energy use, reducing costs and environmental impact.

Conclusion

Sizing a centrifugal pump correctly is crucial. It ensures efficiency and longevity. Start by understanding your system’s needs. Check flow rate and head requirements. Use the pump curve as a guide. Match your system with the right pump model. This prevents costly errors and downtime.

Also, consider energy consumption and maintenance needs. A well-sized pump saves money and resources. Consult experts if unsure. Proper sizing leads to optimal performance. So, take time to assess all factors. This careful approach guarantees success in pump selection.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance