Are you aware of the crucial role water plays in industrial processes? Clean water is not just a necessity; it’s the lifeblood of many industries.

However, with increasing demands and environmental concerns, ensuring that your water supply is safe and reliable is more important than ever. That’s where industrial water filtration technologies come into play. These innovative solutions can transform your water quality, optimize your operations, and even save you money.

Imagine the benefits of reduced downtime, improved product quality, and compliance with regulations—all achievable through effective water filtration. You’ll discover the different types of industrial water filtration technologies available today, how they work, and what they can do for your business. By the end, you’ll have the knowledge you need to make informed decisions that could enhance your operations and protect your bottom line. Don’t miss out on the opportunity to elevate your water management strategy!

Importance Of Clean Water In Industries

Clean water is very important for industries. It affects production and safety. Using filtered water helps avoid problems. Dirty water can cause equipment damage. This leads to costly repairs.

Industries need to meet health standards. Clean water ensures a safe workplace. It also protects the environment. Businesses face penalties for pollution. Investing in water filtration saves money in the long run.

Many industries use different filtration technologies. Each type has its own benefits. Choosing the right system helps improve efficiency. It also supports sustainable practices. Clean water is vital for success.

Common Contaminants In Industrial Water

Industrial water can have many contaminants. These can harm the environment and health. Common contaminants include:

- Heavy metals:Lead, mercury, and cadmium are harmful.

- Microorganisms:Bacteria and viruses can cause diseases.

- Pesticides:Chemicals from farming can pollute water.

- Nutrients:Nitrogen and phosphorus lead to algae blooms.

- Solvents:Chemicals used in industries can contaminate water.

Each of these contaminants needs special treatment. Proper filtration is key. It helps ensure clean and safe water.

Key Water Filtration Technologies

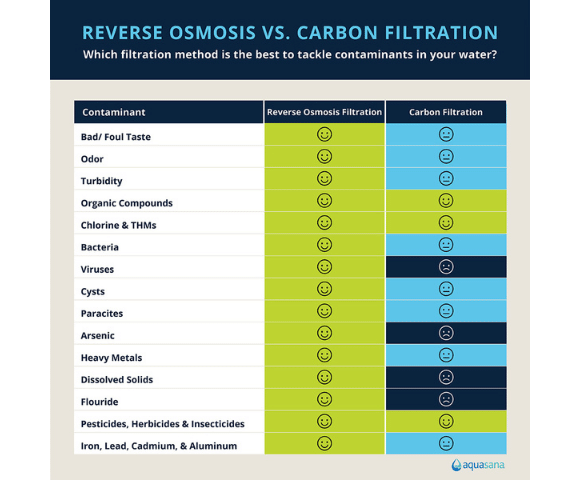

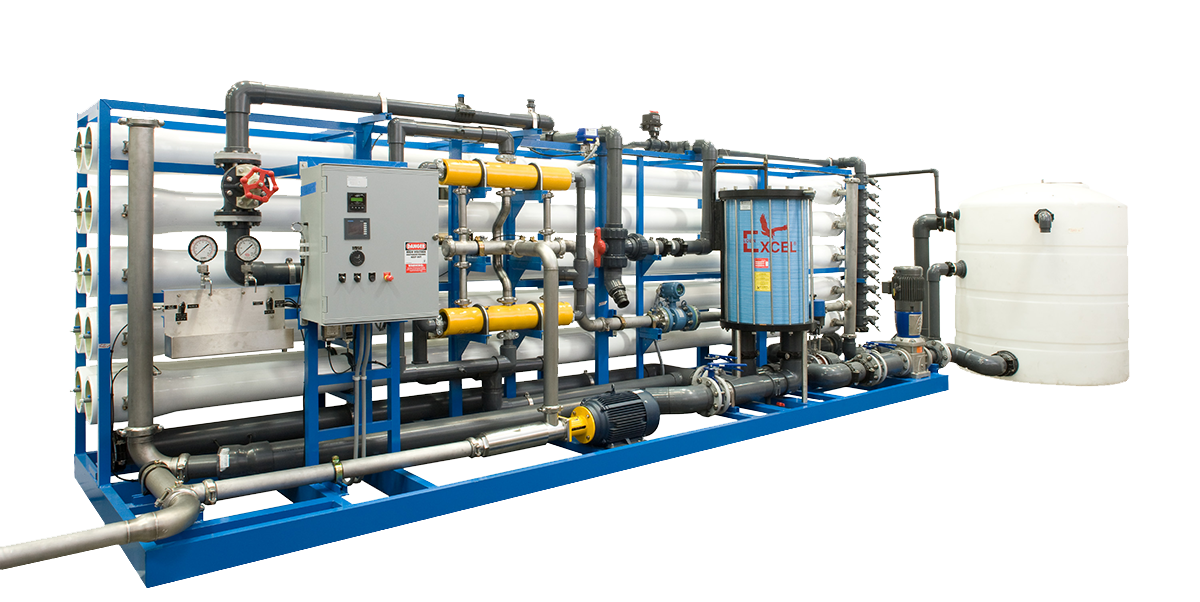

Reverse Osmosis Systemsuse a thin membrane. This membrane removes tiny particles. It helps make water clean and safe. Many industries use these systems.

Ultrafiltration Membranesfilter water using pressure. They catch larger particles and bacteria. This method is good for clear water.

Activated Carbon Filtersremove bad smells and tastes. They trap impurities from water. These filters are simple and effective.

Ion Exchange Resinsswap harmful ions with safe ones. They help soften water. This process is important for many uses.

Innovative Filtration Solutions

Nanofiltration methodsuse special membranes. These membranes remove small particles. They also let some minerals pass. This method is good for softening water.

Electrodeionization techniqueswork by using electricity. They remove ions from water. This method is efficient and uses less energy.

Advanced oxidation processescreate strong chemicals to clean water. These chemicals break down harmful substances. This method helps in treating difficult pollutants.

Benefits Of Modern Filtration Systems

Modern filtration systemsoffer many benefits. They improve process efficiencyin industries. Clean water helps machines run better. This leads to faster production.

Cost savingsare another key benefit. Less energy is used for cleaning water. This reduces overall costs for companies. Savings can be used for other important areas.

These systems also help reduce environmental impact. Cleaner water means less pollution. This protects local ecosystems and wildlife. Companies can show they care about the planet.

Challenges In Industrial Filtration

Handling high-volume demandsin industrial filtration is tough. Systems must process large amounts of water. They need to work quickly and efficiently. This can strain equipment and increase costs.

Dealing with complex pollutantsadds to the challenge. Different industries create unique waste. Some pollutants are hard to filter out. This requires special technologies and methods.

Finding the right balance between cost and effectivenessis crucial. High-quality filters can be expensive. Yet, cheaper options might not perform well. Companies must choose wisely to stay within budget.

Future Trends In Filtration Technologies

AI-driven water quality monitoringimproves the safety of water. Sensors can check water quality in real-time. They send alerts for any problems. This technology helps avoid big issues.

Sustainable filtration materialsare important for the environment. Using natural and recycled materials can reduce waste. These materials also help clean water effectively.

Energy-efficient systemssave money and resources. They use less power to filter water. This makes them better for both the planet and budgets. New designs focus on low energy use.

Frequently Asked Questions

What Are Industrial Water Filtration Technologies?

Industrial water filtration technologies are systems designed to remove impurities from water in industrial applications. These technologies include processes like reverse osmosis, microfiltration, and ultrafiltration. They ensure that water meets required quality standards for various industrial processes, enhancing efficiency and sustainability.

How Do Water Filtration Systems Work?

Water filtration systems work by using physical, chemical, or biological processes to remove contaminants. Filters trap particles, bacteria, and other impurities as water flows through them. This results in cleaner, safer water suitable for industrial use, reducing risks of contamination and improving overall system performance.

What Industries Use Water Filtration Technologies?

Many industries utilize water filtration technologies, including pharmaceuticals, food and beverage, and manufacturing. These sectors require high-quality water for production processes. Efficient water filtration helps maintain product quality, comply with regulations, and minimize environmental impact.

What Are The Benefits Of Water Filtration?

The benefits of water filtration include improved water quality, reduced operational costs, and compliance with regulations. Filtration systems enhance the efficiency of industrial processes by ensuring a consistent supply of clean water. Additionally, they help protect equipment from damage caused by contaminants.

Conclusion

Understanding industrial water filtration is essential. These technologies improve water quality for many industries. They ensure safe and clean water for various processes. Choosing the right filtration system can save money and enhance productivity. Regular maintenance is key for optimal performance.

Investing in quality filtration leads to better results. As industries grow, so does the need for effective water solutions. Stay informed about the latest technologies. This knowledge helps businesses make smart choices. Clean water is vital for a sustainable future.

Prioritize it for your operations today.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance